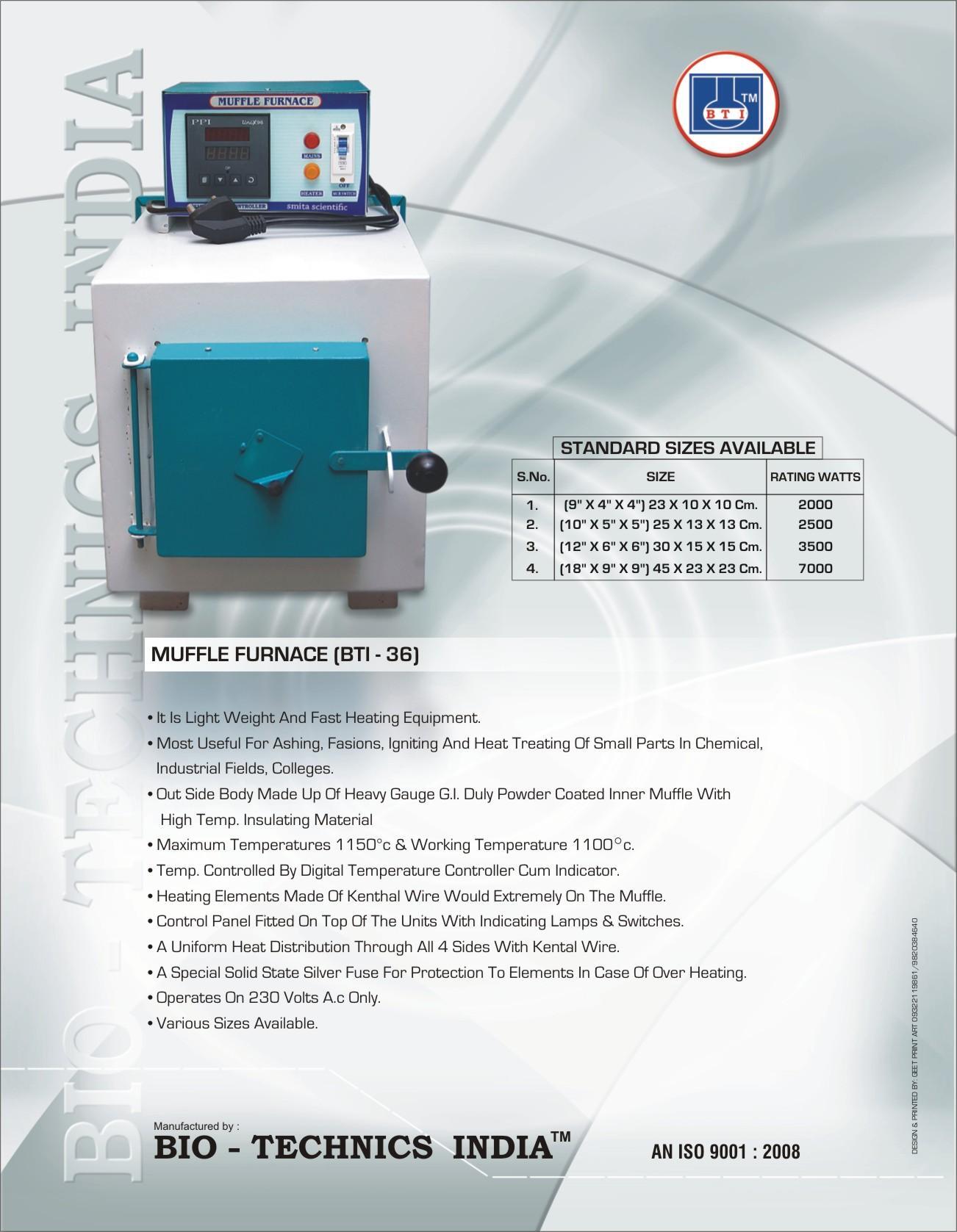

Muffle Furnace

Price 35000 INR/ Number

Muffle Furnace Specification

- Heating Capacity

- 1200C Max

- Shape

- Rectangular

- Control Type

- Digital PID Controller

- Features

- Low Heat Loss, Fast Heating Rate, Insulated Door, Energy Efficient

- Display Type

- Digital Temperature Display

- Power Supply

- Single Phase, 50 Hz

- Accuracy

- +/- 2C

- Temperature Resistance

- Up to 1200C

- Type

- Muffle Furnace

- Dimension (L*W*H)

- 220 x 120 x 90 mm (inner chamber)

- Equipment Type

- Laboratory Furnace

- Equipment Materials

- Mild Steel Outer Body & High-Grade Ceramic Fibre Insulation

- Power

- 2 kW

- Voltage

- 220-240 V

- Material

- Ceramic Fibre Wool and Mild Steel

- Application

- Ash Content Determination, Materials Testing, Laboratory Research

- Capacity (Ltr)

- 2.4 L

- Color

- Grey/Blue

- Furnace Weight

- 35 kg approx.

- Door Type

- Front Opening, Insulated

- Temperature Uniformity

- ±10°C

- Sensor Type

- K-Type Thermocouple

- Chamber Material

- High Alumina Ceramic Fiber

- Insulation Thickness

- 100 mm

- Controller Type

- Microprocessor-based Digital PID

- Heating Element Material

- Kanthal (A1) wire

- Operating Temperature

- Up to 1150°C continuous

- Accessories Provided

- Ceramic Tray, Instruction Manual, Power Cord

- Safety

- Over-Temperature Protection, Auto-Cut-off

- Surface Finish

- Powder Coated

About Muffle Furnace

Muffle Furnace :( 1130 C) with Digital Temp.

Controlled

Model : BTI-36

Size in inches : 12x6x6

Rating watts : 3500

Specification:

Construction: Outer Body made of Mild Steel

powder coated. Inner Body made of ceramic

Muffle Kumar make.

Insulation: Special type ceramic Insulation

between body for Insulation.

Coil: A1 swaden make coil for long

lasting.

Temp Range: 400 C to max 1150C.

Accuracy: +/- 3 deg.

Temp Controlled by: PID Dual display to view

set & current temp.

Safety: Special type thermocouple fuses to

protect overheating.

Sensor: 'K type calibrated sensor

Make : Bio technics

Advanced Structure & Heating Performance

This muffle furnace utilizes high alumina ceramic fiber and a Kanthal (A1) wire element, supported by a substantial 100 mm insulation layer. Such construction fosters rapid heating and outstanding temperature resistance while minimizing heat loss. Its digital PID controller ensures precise temperature management, ideal for complex laboratory and research settings where accuracy is paramount.

User Safety and Accessibility Features

Designed with laboratory safety in mind, the furnace comes equipped with over-temperature protection and an automatic cut-off mechanism to prevent unsafe conditions. The insulated front-opening door and cool-to-touch powder-coated exterior enhance handling, while the digital display allows for effortless monitoring and control.

Versatile Laboratory Applications

Perfect for ash content determination, material testing, and laboratory research, this muffle furnace caters to various scientific needs. With a stable chamber environment, temperature uniformity, and included ceramic tray, it streamlines preparation and analysis for consistent results.

FAQ's of Muffle Furnace:

Q: How does the muffle furnace maintain temperature uniformity inside the chamber?

A: The furnace utilizes high alumina ceramic fiber insulation and a Kanthal (A1) heating element, along with a microprocessor-based digital PID controller and a K-type thermocouple sensor, which collectively deliver temperature uniformity of 10C throughout the chamber.Q: What materials can be safely tested or processed in this laboratory muffle furnace?

A: This furnace is ideal for a variety of applications including ash content determination, materials testing, and general laboratory research using samples that require controlled heating up to 1150C (continuous) or a maximum of 1200C.Q: When is it recommended to use the included over-temperature protection and auto cut-off features?

A: These safety features are active during every operation; they monitor the internal conditions and automatically shut off the furnace if the set temperature is exceeded, protecting both the sample and equipment from damage.Q: Where should this muffle furnace be installed in a laboratory?

A: Place the furnace on a stable, heat-resistant surface in a well-ventilated area, away from flammable materials. Ensure suitable access to a single-phase 220-240V, 50 Hz power supply for safe operation.Q: What process does the digital PID controller follow to achieve accurate temperature control?

A: The digital PID controller continuously monitors chamber temperature via a K-type thermocouple, comparing it to the desired setpoint. It automatically adjusts the power supplied to the Kanthal heating elements to ensure rapid reaching and stable maintenance of the programmed temperature, within an accuracy of 2C.Q: How energy efficient is this furnace during operation?

A: With 100 mm thick insulation and low heat loss design, the muffle furnace minimizes energy consumption while maintaining fast heating rates and stable internal temperatures, making it energy efficient for routine laboratory use.Q: What are the main benefits of using this particular muffle furnace in laboratory research?

A: Users benefit from precise temperature control, safety features like over-temperature protection, durable construction with high alumina ceramic fiber, and convenient accessories, all of which foster reliable, reproducible results in research and materials testing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in lab instruments Category

Ultra Bath Sonicator

Price 20500.00 INR / Number

Minimum Order Quantity : 1 Number

Accuracy : 2C (temperature) C

Temperature Resistance : Up to 80C

Application : Laboratory, Medical, Cleaning Instruments

Power Supply : Standard AC

Digital Water Bath

Price 53000.00 INR / Number

Minimum Order Quantity : 1 Number

Accuracy : 1C C

Temperature Resistance : Up to 100C

Application : Ideal for Laboratories, Research, Medical, Pharmaceutical Use

Power Supply : Electric

Melting Point Apparatus

Price 40000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Accuracy : 1C C

Temperature Resistance : Up to 350C

Application : Determination of melting point of substances

Power Supply : 230 V AC, 50 Hz

Karl Fischer Titrator

Price 41500 INR / Number

Minimum Order Quantity : 1 Number

Accuracy : 0.2% for water content determination C

Temperature Resistance : Up to 80C

Application : Moisture content analysis in liquids, solids, and gases

Power Supply : 230 V AC

&

"We are dealing in bulk orders only."

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free